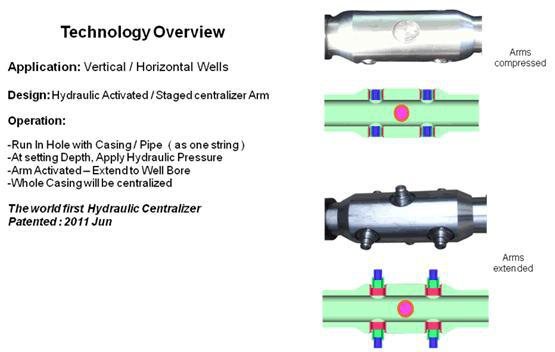

Hydraulic Tubing Centralizer

For well work-over and intervention, Our patented tubing centralizer, usually used in through-tubing applications, employs hydraulic force to energize the centralizer arms. It consists of double sleeves design. The outer sleeve while inserting the tubing into the well keeps the centralizer arms in their retract position. While reaching the end of the tube, the inner water pressure pushes the centralizer arms out into contact with the inner surface of the tube, thus keeping the tubing in central position to avoid excess wear by friction against the tube. The relatively large expansion required for this is not generally within the operating range of conventional centralizer models.

• High stress and pressure grade: apply in fracturing

• Large bare hole access: good for operation

• Arms: large holding power, arms shall not return after casing decompressed

• Easy RIH: since the design is short and with chamfering, very easy Run In Hole

• Performance and figures

• OD: 7.00’’ (Compressed)

• OD: 10.00’’ (Extended)

• ID: 4.778"

• Connection: 5.500" 20# LTC Box, 5.500" 20# LTC Pin, BTC

• Working Pressure: 10000 psi •Opening Pressure: 1,500 psi +15%

• Material: 41XX/P110 STEEL •Temperature: 275F Shear pin: 750psi of 2ea, 1100psi of 4ea, 2000psi of 8ea

|